Can A Broken Caretaker 99 Gearbox Cause High Filter Pressure?

Take a question near whatever of our products, including infloor systems, drains, Virginia Graeme Baker Compliance, etc? Leave a comment beneath and I will do all I can to respond your questions.

Basic Troubleshooting for Paramount In-floor Cleaning Systems

IMPORTANT- Ever Have THE ORIGINAL PARAMOUNT LAYOUT WITH YOU BEFORE TRYING TO TROUBLESHOOTING A POOL

PCC2000 – Puddle VALET – PV3-Cyclean

Single PUMP Arrangement (Very Rare with PCC2000)

Heads not cleaning all over pool.

Main drain is not open to sixty % or more. In floor systems only clean thru the main drain, non the skimmer. The skimmer should be set to simply let the water to become over the weir.

If water valve has a gauge, force per unit area should be 18 PSI or over, and filter pressure should be no less than 24 PSI and non over 32 PSI.

- A. If the pressures are not right on the water valve or filter, clean the filter and recheck the pressures.

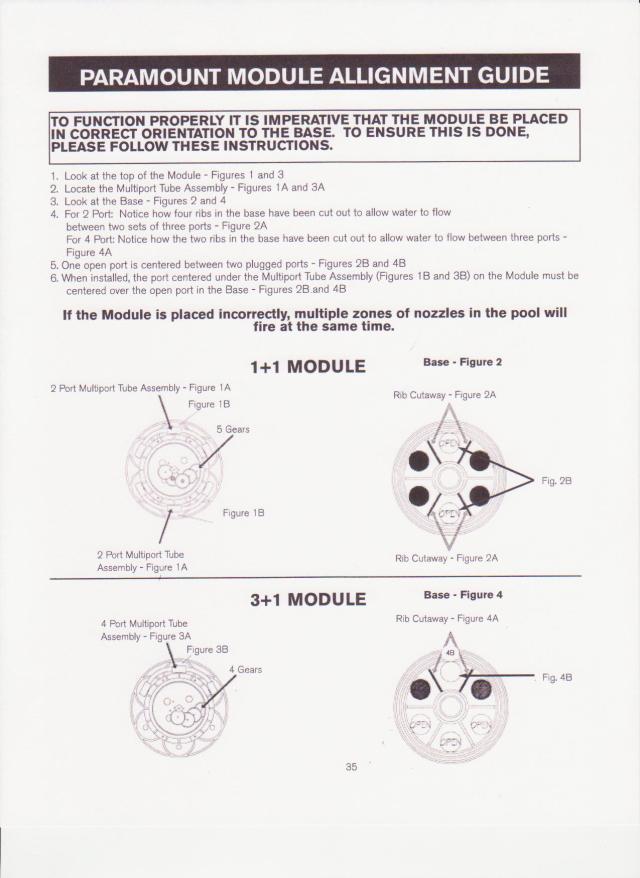

- B. If two or three valves are on the system the second valve should be fifteen# or higher

When on, and should be at 0 PSI when off. The second valve should come on every 3 to 6 minutes and run for three to 6 minutes at which time both valves will have pressure on them. If the pressures are not right the slave valve is probably bad. Ever PAY ATTENTION TO HOW THE MODULE WAS POSITIONED IN THE VALVE Base of operations Earlier TAKING Information technology OUT. TRY CLEANING THE MODULE Before REPLACING. If a client has removed the module with out mark how information technology become back in they can remove the other valve and put water in the center port to see which holes it comes out of in the base. These three holes will be the ones that the tubes on the special module go over.

- C. Other possible problems with low pressure level on the valve gauge.

- a. Pump impeller plugged.

- b. Pump basket full.

- c. Air leak at pump lid O-ring or some other place on the suction side of the pump.

- d. Return or spa valve open up.

PCC – POOL VALET – PV3-Cyclean

BOOSTER PUMP Arrangement

Same every bit above except cleaning filter will non affect the pressure level on the water valve.

ONE OR Ii CIRCUITS Only OR Ane OR Ii HEADS, ARE Not CLEANING Just THE REST OF THE Puddle IS Make clean.

Check nozzles for existence plugged or not rotating properly.

- A. When checking for plugged nozzles run the pump afterward the nozzle has been removed to make sure that the line is not muddied.

DO Non REMOVE MORE THAN One NOZZLE AT A TIME. Each nozzle may be different.

IF NOZZLES ARE Non PLUGGED AND LINE IS Clean Cheque ORIFICE SIZES PER THE PARAMOUNT PLAN.

Pool Valet: 60 GPM per circuit

Each three/8″ hole is 10 GPM.

PV-iii/Cyclean: 60 GPM per excursion.

5/viii″ = 20 GPM

3/8″ = 10 GPM

¼" = 5 GPM

PCC: 50 GPM per excursion.

¾" = 50 GPM

½" = 25 GPM

iii/eight″ = ten GPM

¼" = vi GPM

SPECIAL THINGS TO LOOK AT ON PCC SYSTEMS

Fixed nozzles placement and pressure

Downwards jet placement and bending-

1 When installing or checking a PCC nozzle, always double check the nozzle for the correct side and right nozzle size existence open and used.

- When you observe a plugged nozzle, or line, always clean out the nozzle and too turn on the pump on that port to brand certain the line is gratuitous of debris.

- All lines of the PCC system should equal 50 gpm. ¾" nozzle = 50 gpm. ½" nozzle = 25 gpm. 3/8″ nozzle = 12gpm.

- If your having bug with the pool not cleaning check for at least 60-seventy% open on the main bleed and try brushing clay and debris towards the main drain, if information technology seems to blow away from the master bleed instead of going into it, reduce the fixed nozzle size. This is of course after you take adamant that they were facing the proper direction.

Avant-garde Problem SHOOTING PARAMOUNT INFLOOR CLEANING SYSTEMS

Water Valve

- one. If not working e'er try to wash off the module to clean off clay and cheque for turning by rotating the inside gear.

- 2. If a piston is in the open position this does non always mean that the module is bad. As the diaphragms get onetime they get weak and some times exercise not close with out being under pressure in the system.

- iii. The gear that touches the out side gear ring is at the indicate where the cam that opens the piston is. This is how you tin tell which port is the trouble.

- 4. A loftier pressure on one port is an indication of either a plugged nozzle or the wrong nozzle sizing.

- 5. A depression pressure on ane port is an indication of the wrong nozzle sizing.

- half-dozen. A depression pressure on more than than one port could be a bad piston on a module, a plugged pump impeller, an air leak on the suction side of the pump, or on a single pump organization a muddied filter-no by pass on heater-or some blockage or diversion of water before the h2o valve.

- vii. Firing order for valve configurations: all valves rotate clockwise

–Vi port: Runs each of the zones in sequential order, firing each zone individually for xxx-45 seconds (at 18-22 psi.), and then raising the adjacent zone running both zones for 5-ten seconds(at 6-10 psi), then closing the previous zone to run the side by side zone individually for 30-45 seconds, and and then on…

–Nine port: This runs the offset three zones of the pool on the 4 port control valve (wait for the connector tubes on the peak of the valve module which tie the 3 zones together which send water to the adjoining valve), during which only this valve has pressure level, and so sends h2o for iii cycles to the adjoined half-dozen port valve (during which both valves will show pressure, the control valve will exist 1-three psi college), then again back to the control valve for zones 1 thru 3 again. The firing order volition something similar: ane,two,iii,4,v,6,1,two,iii,7,8,9…

–Twelve port: On this organisation, the control valve is a two port valve containing a special 5 gear module which runs at approximately i/iii the speed of our standard 4 gear module (go on in heed that the 4 gear modules have five gears on them, but one is non operation and is beginning). Look for two sets of "jumper tubes" on the top of the module, going outside of the gear plate associates. This control valve sends water to each of the ii six port modules adjoined to information technology for approximately 10-12 minutes, running those half dozen zones for upwards to 3 cycles or more, then transferring to the other half-dozen port valve to exercise the same.

MDX/Main Drain Performance

In order for Paramount cleaning systems to fully clean the pool, it is imperative that the main drain system in the pool be operating properly. Make sure of the following:

- 50% or more of the filter pump suction is dedicated to the MDX/Main drain. This can be accomplished past reducing suction to the skimmers.

- Confirm that the bleed line is clear and that water is moving freely through the drain and the drain line.

- If a debris canister is present on the deck (ADR), make sure the pocketbook/basket inside of it is make clean, and that the balance/blaster line from the ADR to the pool is functioning properly and h2o is being maintained above the internal clear hat at the same level as the pool. A full canister bag means the drain cannot draw enough water which tin lead to a clogged bleed. Consumers should always check and clean the canister bag anytime they clean their skimmers.

- If the bleed is clogged, you may either accept to remove the cover and articulate out the drain, or you may be able to articulate the debris by isolating the drain line at the filter pump and blocking the secondary suction in the pool using a garbage bag or equivalent.

Can A Broken Caretaker 99 Gearbox Cause High Filter Pressure?,

Source: https://kurtatparamount.com/technical-forum/

Posted by: boydurnow1985.blogspot.com

0 Response to "Can A Broken Caretaker 99 Gearbox Cause High Filter Pressure?"

Post a Comment